-

Праздник середины осени - Праздник середины осени и второй по величине праздник в Китае2023-09-28Праздник середины осени & ndash; Праздник середины осени и второй по величине праздник в Китае в этом году, жители материкового Китая отдыхают 29 сентября 2023 года. Фактически & # 39; С подключен.

Праздник середины осени - Праздник середины осени и второй по величине праздник в Китае2023-09-28Праздник середины осени & ndash; Праздник середины осени и второй по величине праздник в Китае в этом году, жители материкового Китая отдыхают 29 сентября 2023 года. Фактически & # 39; С подключен. -

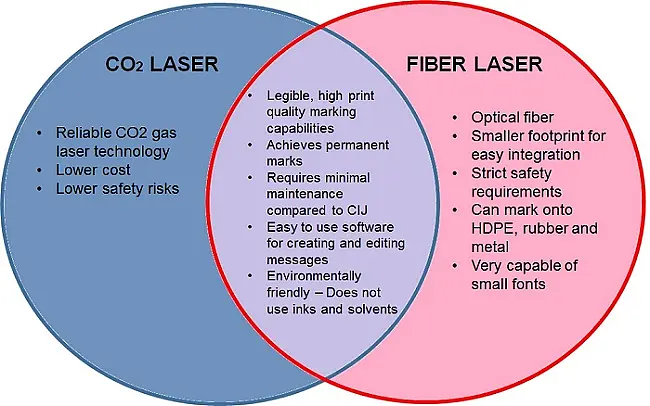

В чем разница между лазерным резаком на углекислом газе и волоконно - оптическим лазерным резаком?2023-08-30Лазерные режущие машины CO2 и волоконно - оптические лазерные режущие машины используются для резки различных материалов, но они отличаются с точки зрения источника лазера, эффективности, производи...

В чем разница между лазерным резаком на углекислом газе и волоконно - оптическим лазерным резаком?2023-08-30Лазерные режущие машины CO2 и волоконно - оптические лазерные режущие машины используются для резки различных материалов, но они отличаются с точки зрения источника лазера, эффективности, производи... -

В последние годы Цзинань занимает первое место в стране по экспорту и экспорту лазерного оборудования2023-08-19В Цзинань, Geely; В Smart New Energy Cars переход от стали к самодельным деталям автомобиля занимает всего 12 секунд. НБСП; На заводе Volvo Smart, используя сигналы 5G для наведения и

В последние годы Цзинань занимает первое место в стране по экспорту и экспорту лазерного оборудования2023-08-19В Цзинань, Geely; В Smart New Energy Cars переход от стали к самодельным деталям автомобиля занимает всего 12 секунд. НБСП; На заводе Volvo Smart, используя сигналы 5G для наведения и -

Мини - лазерная режущая машина Rittu 20102023-07-06Небольшие лазерные режущие машины относятся к лазерным режущим машинам, предназначенным для небольших производственных площадей и небольших площадей, и являются популярным оборудованием в лазерных ...

Мини - лазерная режущая машина Rittu 20102023-07-06Небольшие лазерные режущие машины относятся к лазерным режущим машинам, предназначенным для небольших производственных площадей и небольших площадей, и являются популярным оборудованием в лазерных ... -

Цзинань ускоряет рост как « третий полюс лазерной промышленности Китая»2023-05-20В начале лета неограниченный Цзинань открыл еще одну встречу, которая привлекла внимание лазерной промышленности. 6 мая в Пекине открылся Всемирный конгресс лазерной промышленности 2023 года

Цзинань ускоряет рост как « третий полюс лазерной промышленности Китая»2023-05-20В начале лета неограниченный Цзинань открыл еще одну встречу, которая привлекла внимание лазерной промышленности. 6 мая в Пекине открылся Всемирный конгресс лазерной промышленности 2023 года -

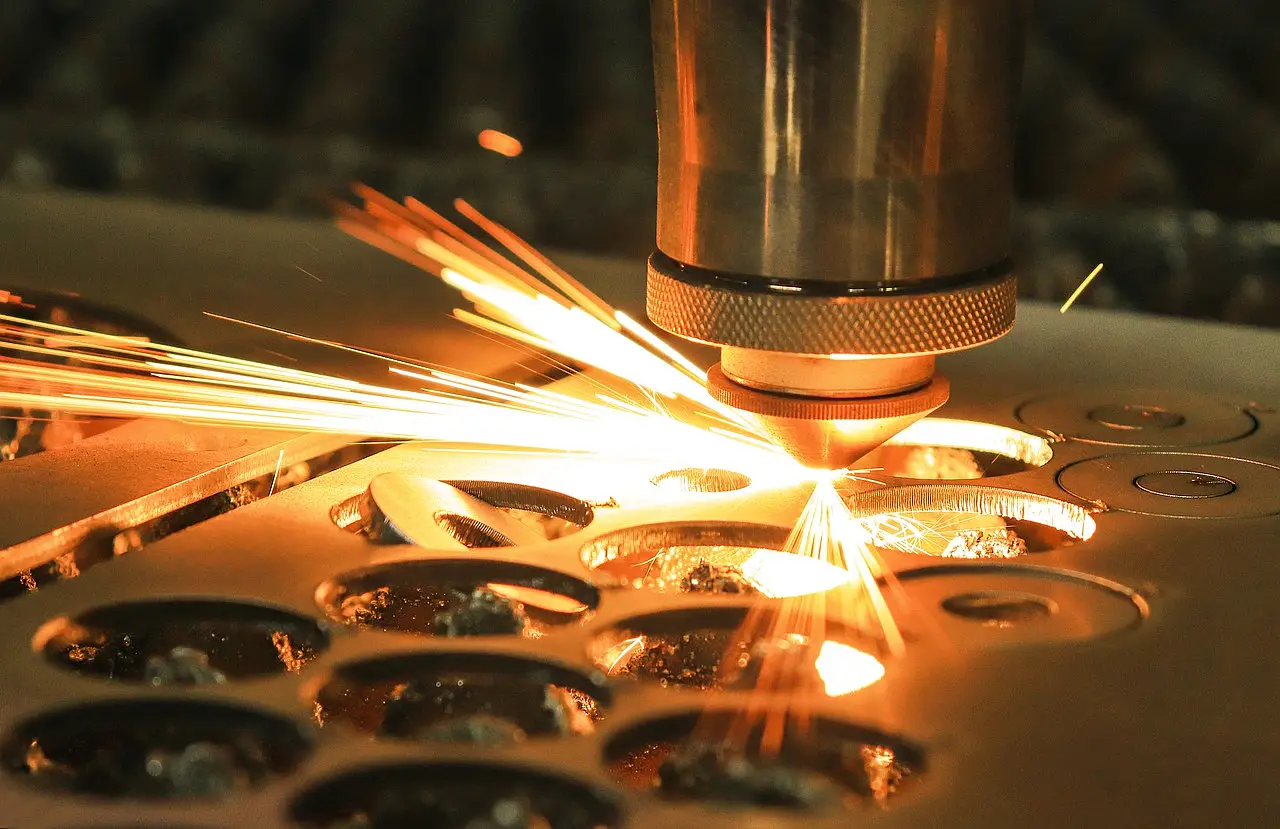

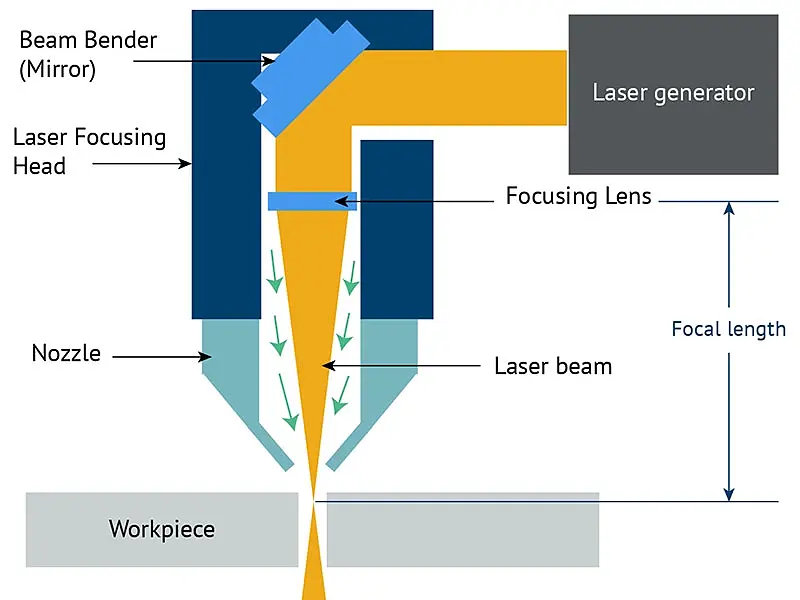

Каков принцип работы лазерной машины для обработки металлических листов?2023-03-23Лазерные машины могут обрабатывать сплавы, цветное железо и низколегированную сталь. Лазерная резка считается одним из наиболее эффективных и рентабельных методов резки металлических заготовок. Исп...

Каков принцип работы лазерной машины для обработки металлических листов?2023-03-23Лазерные машины могут обрабатывать сплавы, цветное железо и низколегированную сталь. Лазерная резка считается одним из наиболее эффективных и рентабельных методов резки металлических заготовок. Исп... -

Ключевые технологии волоконно - оптических лазеров все еще нуждаются в прорыве2023-03-13Китай & # 39; Китайский рынок волоконно - оптических лазеров превысил 10 млрд. юаней, а рынок лазерного оборудования превысил 100 млрд. юаней. В настоящее время ключевые технологии волоконно - опти...

Ключевые технологии волоконно - оптических лазеров все еще нуждаются в прорыве2023-03-13Китай & # 39; Китайский рынок волоконно - оптических лазеров превысил 10 млрд. юаней, а рынок лазерного оборудования превысил 100 млрд. юаней. В настоящее время ключевые технологии волоконно - опти... -

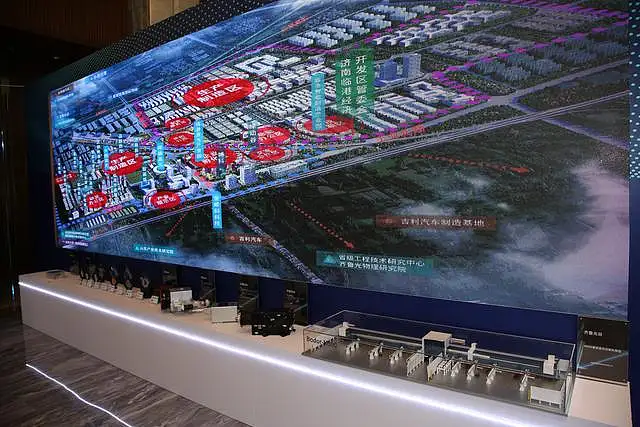

Цзинаньская зона экономического развития Lingang создает новую высоту лазерной промышленности2023-02-22В целях осуществления муниципальной инициативы & quot; Прорывной год проекта "; Цзинаньская зона развития Lingang прочно утвердилась & quot; Проект для короля & quot;

Цзинаньская зона экономического развития Lingang создает новую высоту лазерной промышленности2023-02-22В целях осуществления муниципальной инициативы & quot; Прорывной год проекта "; Цзинаньская зона развития Lingang прочно утвердилась & quot; Проект для короля & quot; -

Решение для лазерной маркировки антигенных реагентов2023-01-10В медицинской сфере продукты могут прямо или косвенно влиять на здоровье потребителей. До фактического использования почти все не уверены в его качестве. Таким образом, внешний вид

Решение для лазерной маркировки антигенных реагентов2023-01-10В медицинской сфере продукты могут прямо или косвенно влиять на здоровье потребителей. До фактического использования почти все не уверены в его качестве. Таким образом, внешний вид -

Программа работы лазерной режущей машины2022-11-07металлические материалы являются важной продукцией обрабатывающей промышленности. если мы хотим в полной мере использовать этот материал, мы должны изготовлять его из режущего оборудования. лазерны...

Программа работы лазерной режущей машины2022-11-07металлические материалы являются важной продукцией обрабатывающей промышленности. если мы хотим в полной мере использовать этот материал, мы должны изготовлять его из режущего оборудования. лазерны...